Our R&D efforts are focused on three key areas.

1. Continuous Development

We are committed to the continuous improvement of our existing product lines through ongoing research and development initiatives.

Our dedicated team of engineers and designers continually explores new materials, manufacturing techniques, and design methodologies to enhance the performance, reliability, and efficiency of our components.

2. Prototype Development

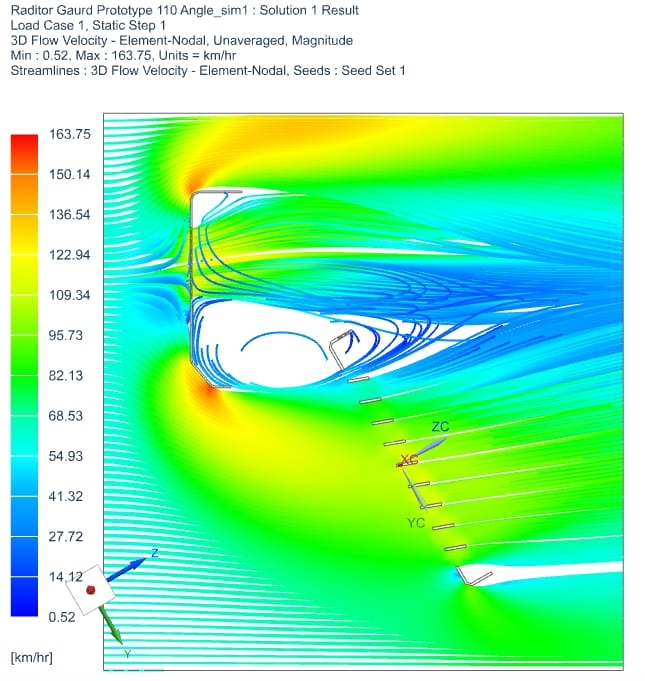

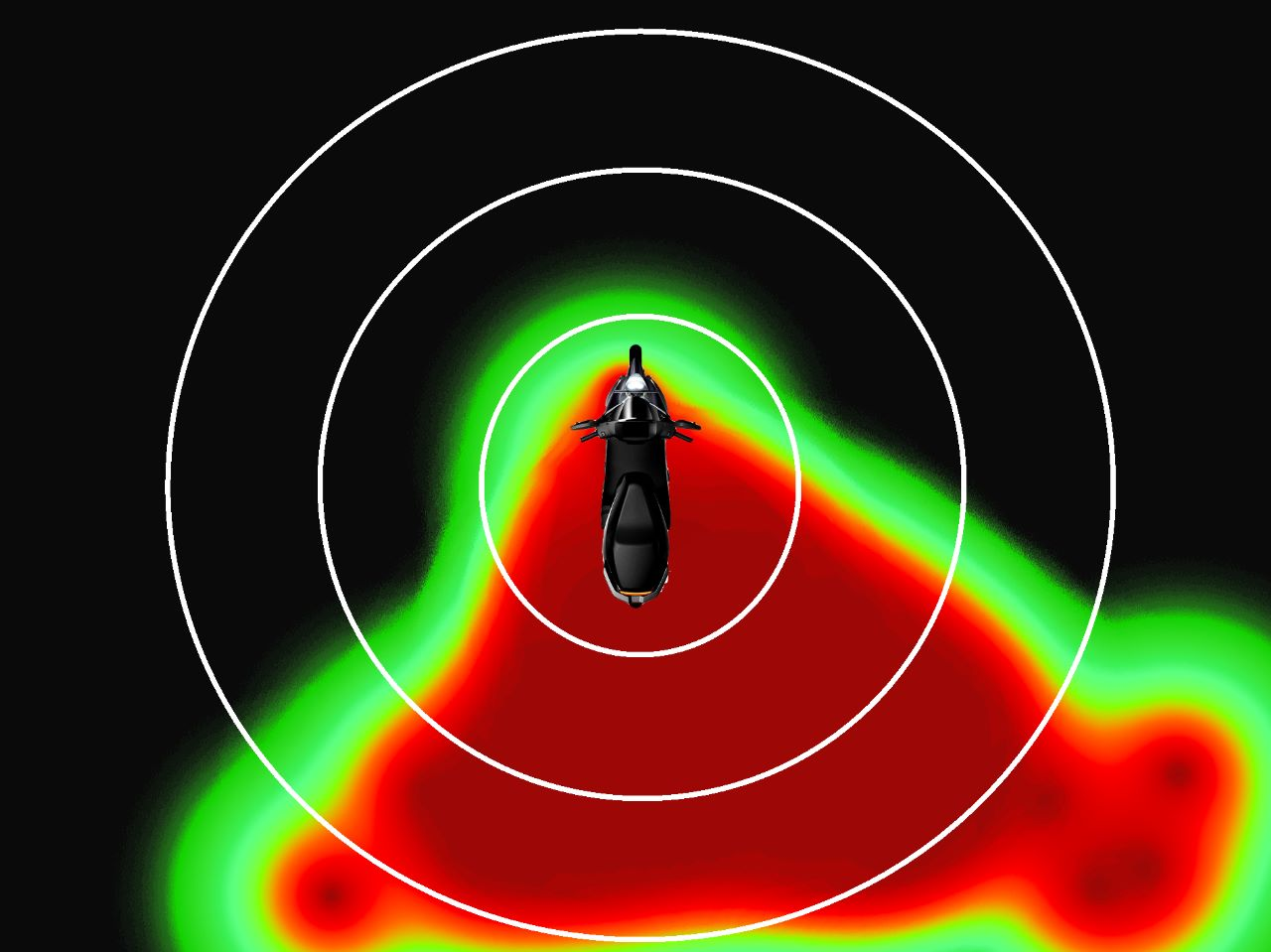

Our R&D team collaborates closely with customers and industry partners to identify emerging trends, technological advancements, and market opportunities.

Leveraging cutting-edge technologies such as 3D printing, virtual prototyping, and simulation, we rapidly develop and test prototype components, bringing new concepts to life and validating their feasibility and performance.

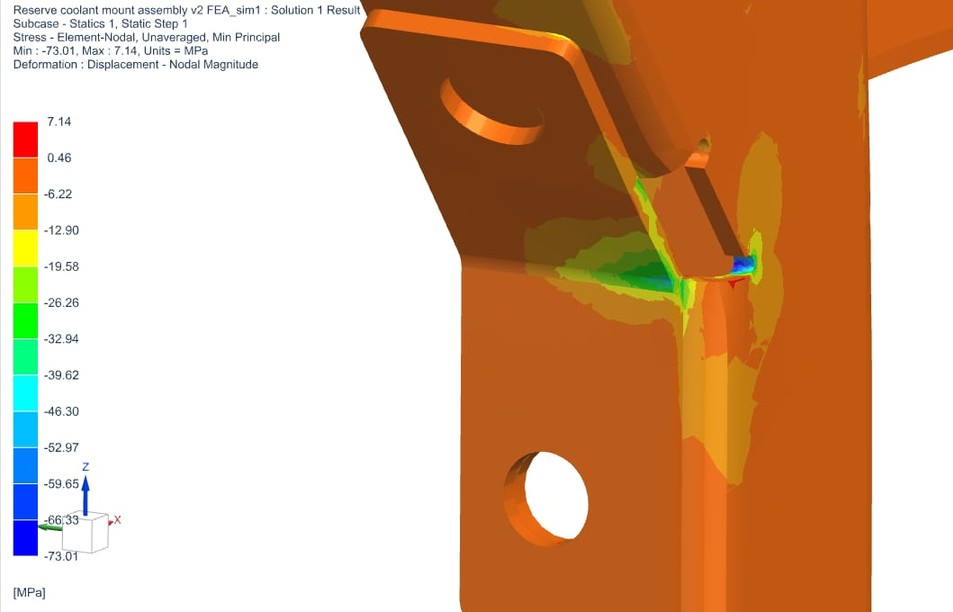

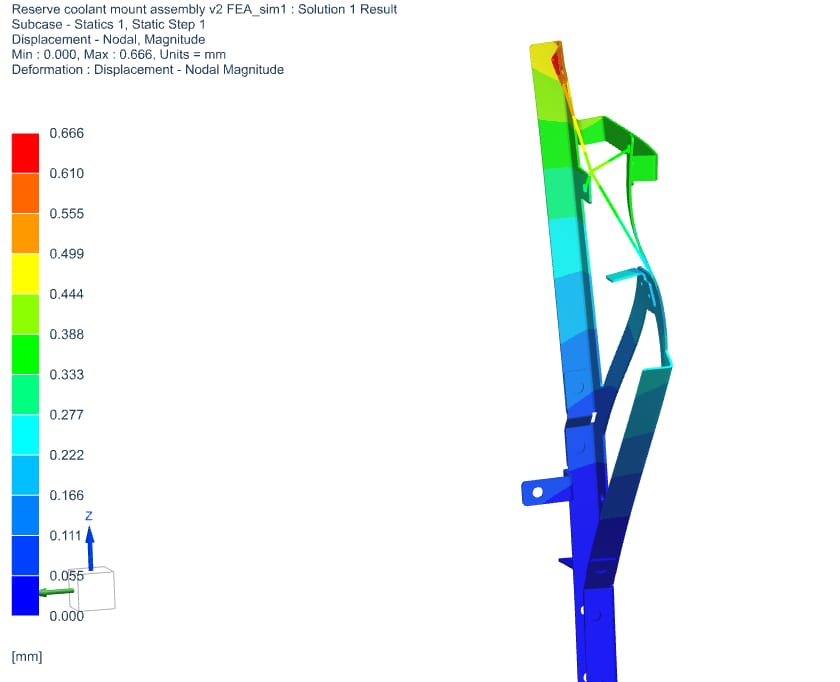

3. Analysis & Engineering Research

Finite Element Analysis (FEA) serves as an integral aspect of our quality assurance process. Through FEA, we conduct exhaustive analyses for every part, evaluating their structural integrity, durability, and performance across diverse operational conditions. By simulating real-world scenarios and applying advanced engineering principles, we ensure that our parts not only meet rigorous quality standards but also surpass customer expectations.